|

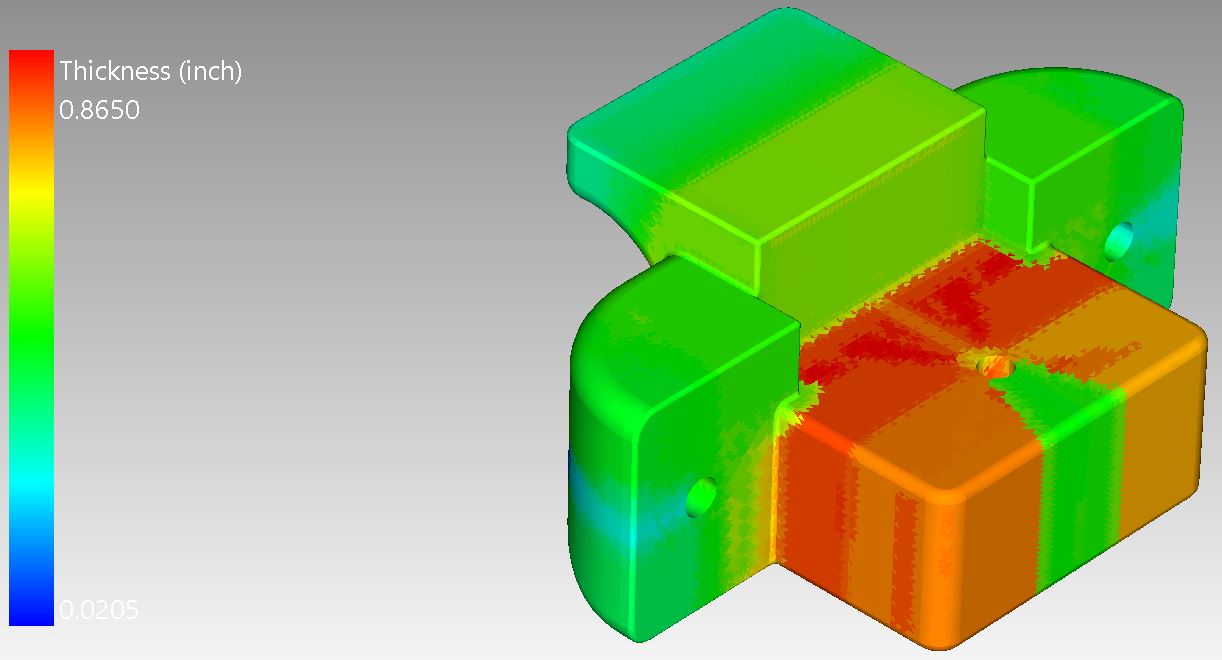

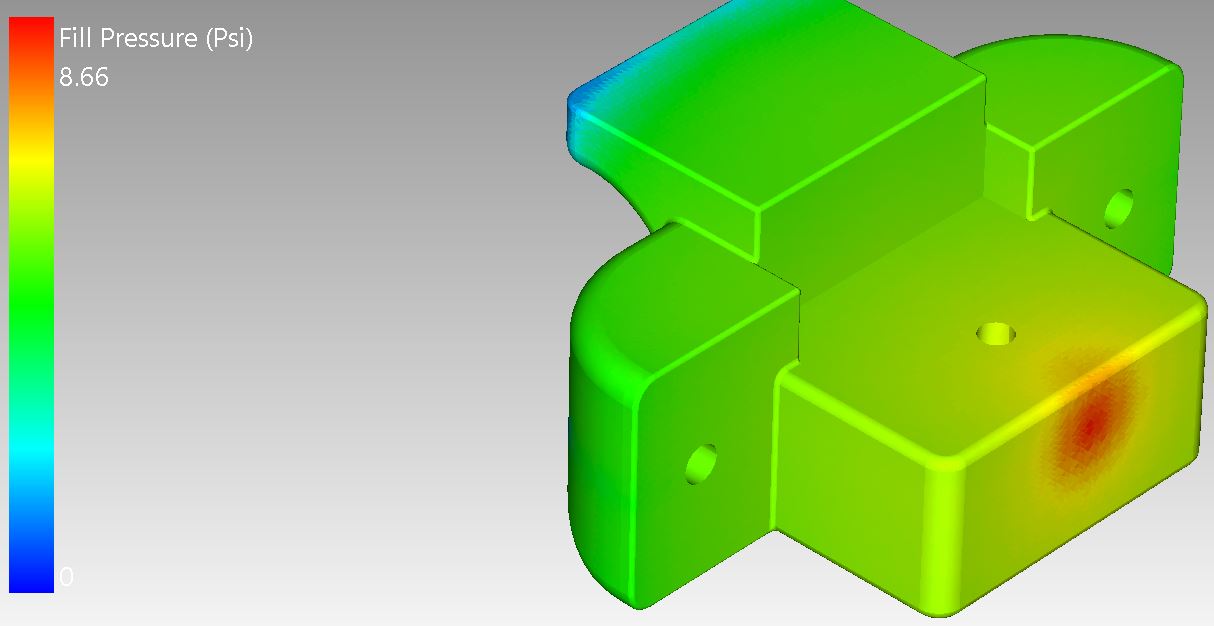

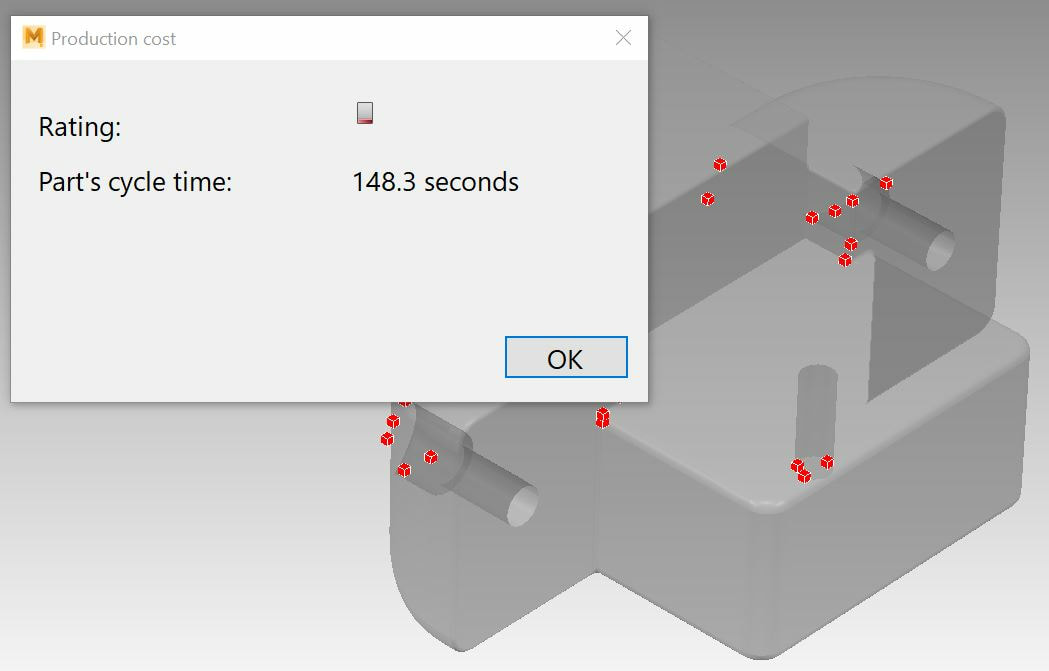

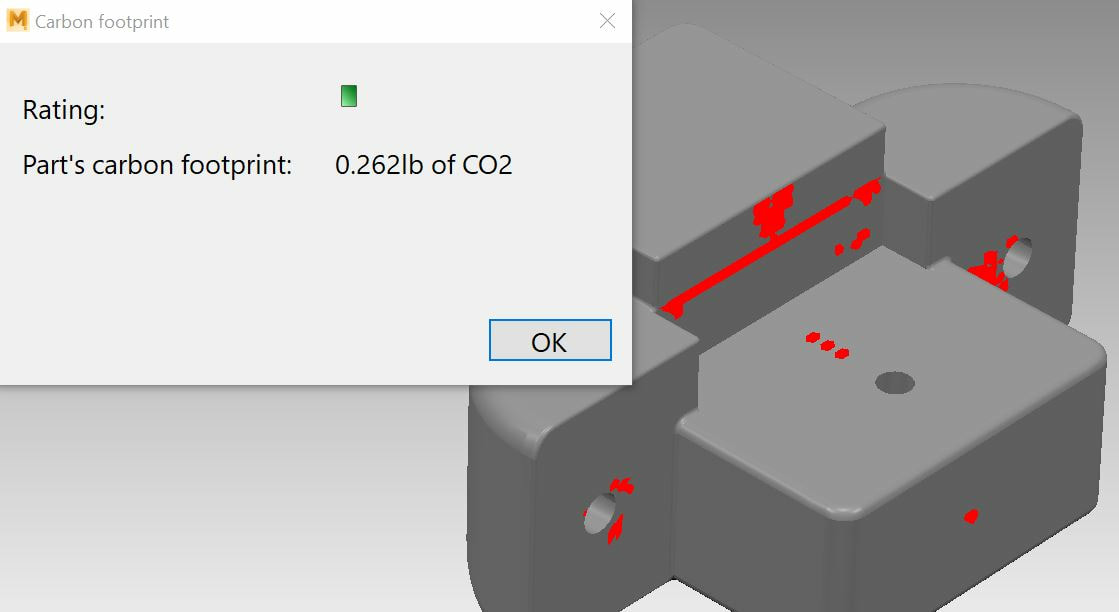

As a part of our continuous improvement we offer Moldflow® analysis to simulate theoretical filling patterns, pressure gradiants, and plastic material behavior in molding. This allows us to optimize gate location and part design to help avoid sinks, weld lines, gas burns, short shots and other common undesirable characteristics. This detailed analysis can also lead to lower costs and faster lead time. Additionally, the part can be evaluated for its theoretical cycle time, carbon footprint, embodied water and other factors. It is important that we provide the software with good data input and use our experience and training to interpret the results.

You can see more at this link from Autodesk: https://youtu.be/Xzuy8jMwAC0

1 Comment

|

OfficialThis is the official news blog for Sapona Plastics, LLC. Archives

April 2024

Categories

All

|